VidalesMay 31, 2002 How To Calibrate Touch Screens Touch screens are finding their way into a variety of embedded products. Most touch-enabled devices will require a calibration routine. Here's a good one. Resistive-type touch screens are normally used in cost-conscious designs. Their construction is simple, their operation is well understood, and the hardware and software required to support them is readily available from multiple manufacturers. Despite the advantages of resistive-type touch screens, devices equipped with them almost always require that a calibration algorithm be the first task to run when the final product comes out of the box.

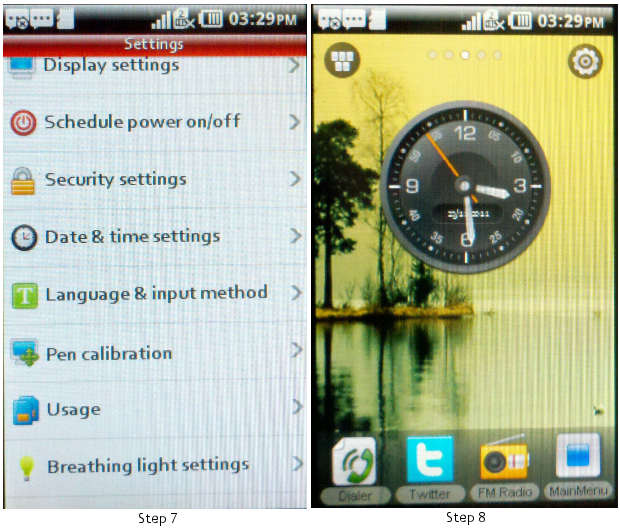

Now, I checked with ASUS Tech and she said that I must locate and Enable the HID. Follow the on screen calibration for Pen input or Touch input settings.

Calibration is necessary because it is difficult to perfectly align a touch screen's coordinates to the display (LCD or otherwise) behind it. If a button or other 'live' feature on the display is to be properly activated, the coordinates of the area touched on the screen must be sufficiently close to the coordinates of the feature on the display.

Otherwise, the software may not correctly act upon the soft button presses. This article proposes a calibration algorithm for resistive-type touch screens that is both efficient and effective. S1 boot fastboot driver win8 version. This algorithm was developed after identifying the sources of touch screen errors and deriving the optimum method for transforming the coordinates provided by the touch screen to match the coordinates of the display. The calibration method requires that three targets or test points-no more, no less-be displayed and touched in sequence to determine the screen's individual calibration factors. These calibration factors are then used to translate screen coordinates into true display coordinates.

Touch screen technology The cross section of a resistive-type touch screen is shown in Figure 1. The construction is simple. Two sheets of glass are brought together to form a sandwich, the interior glass surfaces having been coated with a thin layer of conductive material.

Small glass beads maintain a nominal separation between the conductive surfaces. When a finger or stylus presses against the surface of the glass, the material bends just enough to contact the lower sheet. In this construction the spacing between beads determines the sensitivity of the screen. The closer the beads are, the higher the pressure that must be exerted before the top glass sheet will bend enough to make contact.

Figure 1: Cross section of a resistive-type touch screen Figure 2: Equivalent circuit An equivalent resistive circuit is shown in Figure 2: a touch screen controller (digitizer or A/D) applies the V sources to the ends of one of the conductive layers, while the other conductive layer-on the opposite sheet of glass-plays the role of the potentiometer wiper. The Vtest value read by the digitizer depends on where the glass is touched and the conductive surfaces come into contact.

The controller then translates the voltage reading into a binary quantity representing, for example, the X-coordinate of the point where the screen was touched. The voltage potential is then applied to the second surface's endpoints and the first surface plays the role of the wiper, yielding a value that represents the Y-coordinate.